Inventory Management:

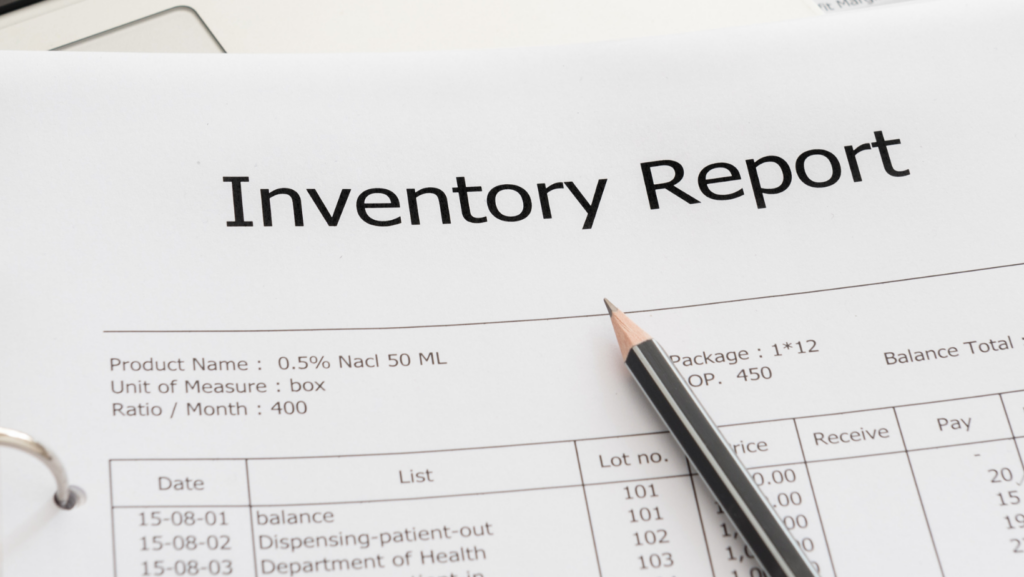

Inventory management is the process of ordering, storing and maintaining an inventory of multiple goods and products. This includes the management of raw materials, components, and finished products.

Drones are one of the aptest modern technology resources for assisting in tedious labor-intensive inspections and surveillance operations in warehouses.

Drones are also used for intralogistics and also transporting some lightweight industrial parts from warehouses to factory assembly lines. In the area of inventory management drones are used for inventory audit, cycle counting, item search, stocktaking, etc.

Why Drones for Inventory Management:

For example, in a physical inventory count method, a person has to walk or travel to the desired location in the warehouse, scan the barcode or QR code of the product and move on to the next desired product location and the process continues. In the above method, the counting process is slow and labor intensive, repetitive and dangerous as people must work at heights. To replace this method, we are introducing a drone for warehouse management. They can frequently update the inventory accuracy and in case of any inventory errors drones can have increased visible trackability.

The drones are doing the autonomous work without manual control, where there is no need for additional material handling equipment (MHE) and allied infrastructure to conduct cycle counting because of the use of automation technology that accomplices drones to carry out flight missions by a pilot.

A conventional system that’s been used for inventory aka warehouse management is software management systems and radio-frequency scanners. As a part of a large manufacturing and supply chain environment, Autonomous warehouse management can have great control over continuous, repeating processes like receiving, sorting, storing, auditing, picking, packing, dispatching and their related database management.

Here, warehouse drones could become a boon for various scale industries when it involves the hectic inventory-related processes, which involve partial operational delay in the part of the facility’s activity so that operators can scan one or all of the items. In this situation, drones could free workers from tedious jobs and enable the warehouse to continue operating normally. The use of warehouse drones in these manual inventories could put an end to the major inconveniences they cause.

The cloud connectivity of drones makes it easy for warehouse stakeholders to adopt autonomous drone fleets into enterprise workflows.

Warehouse drones programmed and designed to read barcode or QR code labels can control inventory simply by flying up and down the facility’s aisles. These drones can also easily access goods located in high-bay racks, which are out of operators’ direct line of sight, they reduce the need for workers to take inventory manually from time to time, which is susceptible to human error. Thus, operators will no longer have to deal with tedious and non-ergonomic tasks. One of the key points to be noted is that these drones lead to less-trafficked working aisles, aiding the safe movement of handling equipment.

Warehouse drones can optimize the process of resource management and operators can focus on enhancing other logistics operations involved in the inventory sector of a company.

Key Challenges:

The existing conventional warehouse infrastructure may not accommodate this new technology, so the suitability must be checked before identifying the right drone technology.

- Labelling accuracy i.e., inconsistencies in pasting the labels in the right places because of varying box sizes.

- Disorganized storage may also lead to inaccuracies.

- The flight time of drones is also a critical challenge too and to overcome this we can deploy a swarm of drones.

We design, develop, deploy and manage drone technologies at MARC Maxbyte Advanced Robotics Centre, Contact us or Book an Appointment.